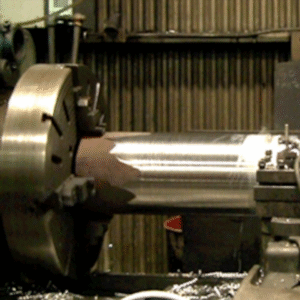

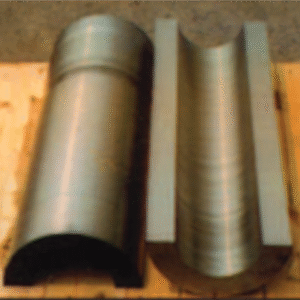

Vulcan Steam Forging Company has been producing the highest quality open die forgings and seamless rolled rings since 1907.

Serving a wide range of industries and applications, we forge all grades including titaniums, aluminums, inconels, high temperature alloys, nickel and copper based alloys, stainless, carbon, and alloy steels.

Vulcan is continuously investing in its people and equipment to provide superior forgings at the lowest cost to our customers.

VS. CASTINGS – – – FORGINGS OFFER

- More strength due to working

- More directional strength due to grain flow

- Little risks of internal defects

- More predictable response to heat treatment- no segregation

- No minimum quantity requirements and no tooling costs

- No wasted time and dollars in machining only to find a defect

VS. FABRICATIONS – – – FORGINGS OFFER

- Cheaper high volume runs

- Can replace multiple piece weldments

- Can eliminate the fab and inspection costs associated with multiple piece weldments and constructions

- More strength – better grain flow – no chance of poor welding/joining

- Simplified production – less steps involved – more consistent product

VS. BAR/PLATE – – – FORGINGS OFFER

- Better variety of grades and sizes

- Better grain flow – far better strength

- More economical use of material – no burn outs, scrapped or excessive machining required

VS. POWDER METALS – – – FORGINGS OFFER

- Higher strength – better grain flow

- Ensured soundness – no defects

- Cost effectiveness

- Ability to produce short runs economically

Industries We Serve

Industrial

Aerospace

Navy & Military

Transit

Power Generation

Oil & Gas

General Fabrication

Quality Certifications

Our list of approvals and certifications.